The Evolution of Fuel Types in Combustion Systems

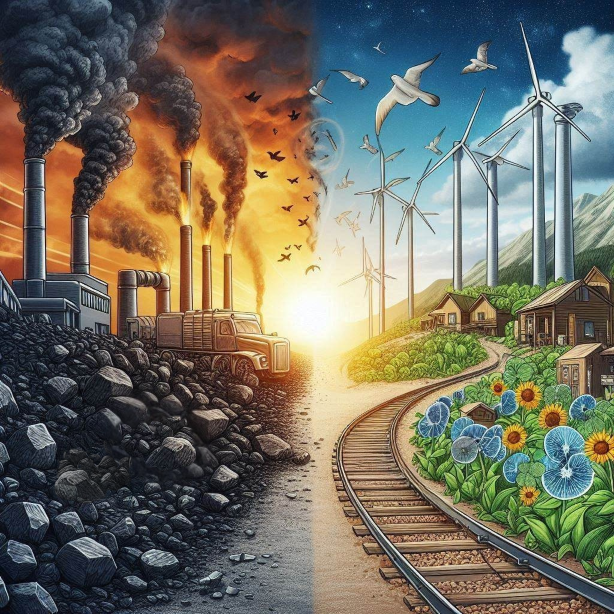

As industries strive to reduce carbon emissions and achieve greater sustainability, the fuel landscape for combustion systems is evolving at a rapid pace. The shift towards alternative fuels like hydrogen, biogas, and waste-derived fuels is transforming industrial processes—offering cleaner, more flexible, and future-ready solutions. With increasing environmental regulations and the global push for decarbonisation, businesses must stay ahead of these changes to remain competitive and compliant.

This week, we’ll explore the growing role of these fuels, their advantages, the challenges they present, and the potential they hold for a low-carbon future.

Fossil Fuels: Their Evolution and the Rise of Alternatives

The world has been using fossil fuels in some form for thousands of years, but large-scale reliance began with the Industrial Revolution.

The Industrial Revolution in the late 18th century saw coal become the dominant energy source, fueling steam engines, factories, and early electricity generation. Eventually, oil began replacing coal in the late 19th and early 20th centuries, particularly with the rise of the automobile and internal combustion engine. In more recent decades, natural gas has become widely used for electricity and heating. Coal has declined in some regions but remains dominant in others, while oil became essential for transport and industry.

While these fuels provided reliable and high-energy output, their environmental impact, particularly in terms of CO₂ emissions, has led to increasing scrutiny. Over time, advances in refining and processing have improved the efficiency and cleanliness of these fuels, with low-sulphur diesel, ultra-low NOₓ natural gas burners, and improved oil formulations reducing harmful emissions. Additionally, oil-based fuels have evolved, with synthetic blends and biofuel-infused compounds offering cleaner alternatives to traditional petroleum-based products. However, despite these advancements, the fundamental issue of carbon emissions remains, prompting a significant shift towards alternative and renewable fuel sources that promise a more sustainable future.

The Growing Use of Alternative Fuels: Hydrogen, Biogas, and Waste-Derived Solutions

Traditional fossil fuels have long powered industrial combustion systems, but with increasing pressure to cut emissions and adopt more sustainable energy sources, businesses are turning to alternative fuel options, including:

Hydrogen: The Future of Zero-Carbon Combustion?

Hydrogen is widely recognised as a game-changer in the energy sector. As a zero-carbon fuel, it produces only water vapour when burned, making it one of the cleanest energy sources available. With advancements in hydrogen production, storage, and distribution, industries are now exploring its viability for large-scale combustion applications. The potential of hydrogen extends beyond reducing CO₂ emissions; it also enhances energy security by diversifying fuel sources. At SAACKE, we have been developing hydrogen-ready burners for decades, capable of operating efficiently with pure hydrogen or hydrogen-enriched fuel blends, ensuring a seamless transition as hydrogen infrastructure expands.

Despite its promise though, hydrogen faces significant hurdles. Green hydrogen – produced using renewable energy – is expensive to generate due to high electricity consumption and limited production facilities. Blue hydrogen, derived from natural gas with carbon capture, still relies on fossil fuels, raising concerns about its overall sustainability. Additionally, hydrogen requires specialised infrastructure, including pipelines and storage solutions, which adds to its adoption cost. Safety concerns, due to hydrogen’s high flammability and storage under high pressure, also present logistical challenges for widespread use. There is still a long way to go in creating a viable Hydrogen network across the UK, but experts around the world are working on the solutions.

Biogas: Turning Waste into Energy

Biogas, produced from organic waste through anaerobic digestion, presents a renewable alternative to natural gas. Not only does it reduce reliance on fossil fuels, but it also supports a circular economy by repurposing agricultural and municipal waste into valuable energy. Biogas combustion can be integrated into existing systems with minimal modifications, making it an attractive solution for industries looking to decarbonise without overhauling their entire infrastructure. Advanced combustion technology rom SAACKE ensures optimal performance when operating on biogas, maintaining efficiency while reducing carbon footprints.

However, while biogas is a sustainable energy source, its production and quality can be inconsistent. The efficiency of anaerobic digestion depends on the feedstock, requiring careful management of waste inputs. Additionally, biogas contains impurities such as hydrogen sulphide and moisture, necessitating cleaning and upgrading processes that add to costs. Large-scale biogas production also requires significant land use, which could compete with food production and biodiversity conservation. Furthermore, methane leaks during production and distribution could offset the environmental benefits, as methane is a potent greenhouse gas.

Waste-Derived Fuels: A Dual Benefit of Waste Reduction and Energy Generation

Waste-derived fuels (WDF) are produced from industrial and municipal waste streams, diverting materials from landfills while providing an alternative energy source. These fuels contribute to a more circular economy, helping industries improve sustainability while achieving greater energy efficiency. SAACKE have developed combustion systems that are designed to accommodate WDF, ensuring consistent and reliable performance across various fuel compositions.

Although waste-derived fuels help reduce landfill waste, their combustion can produce pollutants such as dioxins and heavy metals, requiring stringent emission controls. The variability in waste composition can also lead to inconsistent energy output, affecting combustion efficiency. Furthermore, the collection, sorting, and processing of waste into fuel can be costly and energy-intensive, raising questions about the overall environmental benefits. Some critics argue that promoting waste-derived fuels may discourage efforts to reduce waste generation at the source.

The Advantages of Fuel Flexibility in Industrial Combustion Processes

Fuel flexibility is a critical component of future-proofing industrial operations. With the unpredictable nature of energy markets and evolving regulations, businesses must adopt combustion systems capable of adapting to multiple fuel types. The key benefits of fuel-flexible systems include:

Operational Resilience

Market fluctuations in fuel availability and costs can disrupt industrial operations. Hybrid combustion systems that can seamlessly switch between traditional and renewable fuels provide a safeguard against supply chain uncertainties, ensuring consistent and cost-effective energy generation.

Cost Efficiency

Incorporating biogas and waste-derived fuels into combustion systems can lead to substantial cost savings. By reducing dependence on expensive fossil fuels and leveraging locally available renewable resources, industries can achieve long-term financial benefits alongside environmental gains.

SAACKE has long been at the forefront of developing fuel-flexible combustion solutions, equipping industries with the tools needed to navigate the evolving energy landscape with confidence.

Reduced Carbon Emissions

Transitioning to low-carbon fuels such as hydrogen and biogas enables industries to significantly cut greenhouse gas emissions. With stringent environmental policies coming into effect worldwide, businesses that invest in fuel-flexible combustion systems will be better positioned to meet sustainability targets and avoid potential penalties.

Emerging Fuel Technologies and Their Potential for Reducing Carbon Emissions

The transition to alternative fuels is being accelerated by continuous innovation in combustion technology. Several cutting-edge solutions are emerging to support industries in their decarbonisation journey:

Hydrogen-Ready Burners: Preparing for a Hydrogen Economy

As global investments in hydrogen infrastructure grow, the demand for hydrogen-compatible combustion systems is rising. SAACKE hydrogen-ready burners are designed to operate with pure hydrogen or hydrogen-enriched fuels, delivering zero-carbon combustion without compromising efficiency or reliability.

Hybrid Combustion Systems: The Best of Both Worlds

Hybrid combustion systems blend traditional fossil fuels with renewable options like biogas or waste-derived fuels, striking a balance between performance, cost, and sustainability. These systems provide a gradual transition pathway for industries moving away from conventional fuels, reducing both emissions and operational disruptions. SAACKE se@vis burner management system for example can provide a simultaneous-firing of different fuels, to enable the steady transition away from older fuels to newer, as the costs of these fuels come down.

Synthetic Fuels: The Future of Sustainable Energy

Synthetic fuels, produced using renewable energy sources, offer a promising alternative to fossil fuels. By capturing and utilising CO₂ during production, these fuels can achieve near-carbon-neutral combustion, making them an attractive long-term solution for industrial applications. However, their large-scale production remains costly and energy-intensive, requiring significant investments in infrastructure and renewable power generation.

How SAACKE is Leading the Charge Towards Sustainable Combustion

SAACKE is committed to driving innovation in the combustion industry by delivering state-of-the-art solutions that align with the latest fuel technologies. Our extensive research and development efforts focus on:

- Designing advanced burner systems that maximise efficiency while minimising emissions

- Developing retrofit solutions that enable existing combustion systems to transition to alternative fuels with minimal disruption

- Collaborating with industry leaders to accelerate the adoption of hydrogen, biogas, and waste-derived fuels

With decades of expertise in combustion engineering, SAACKE continues to set the standard for high-performance, fuel-flexible solutions that meet the needs of modern industry.

Exciting Times Ahead

The evolution of fuel types is driving an era of cleaner, smarter combustion systems. By embracing alternative fuels, enhancing fuel flexibility, and adopting emerging technologies, businesses can dramatically reduce carbon emissions while ensuring long-term resilience and efficiency. However, each fuel type presents unique challenges that must be carefully navigated to maximise sustainability benefits.

At SAACKE, we are proud to lead this transformation, delivering future-ready solutions that enable industries to thrive in a more sustainable energy landscape. The future of combustion is here, and with our innovative approach, we are ready to power industries towards a cleaner, more efficient tomorrow.

Want to Know More?

If you are interested to know more about fuel types, fuel switching or how to improve your carbon footprint, Contact our team today and we can arrange a more in-depth presentation for you, or organise an initial free on-site consultation.