MCPD (Medium Combustion Plant Directive) Explained:

Compliance and Best Practices

As global environmental concerns grow, regulatory bodies have introduced more stringent emission standards to combat pollution and reduce the environmental impact of industrial operations. One such standard, the Medium Combustion Plant Directive (MCPD), plays a crucial role in ensuring that medium-sized combustion plants across Europe meet emission limits for key pollutants, including NOx, SOx, and particulate matter (PM). As industries strive to comply with these regulations, understanding the MCPD and adopting best practices for compliance is vital to ensuring both sustainability and operational efficiency.

This article will dive into the key aspects of the Compliance and Best Practices. If you are unsure whether your business is compliant or not, contact us today at webenquiry@saacke.co.uk and a member of the team will be in touch to discuss.

Overview of the MCPD’s Emission Limits for Medium-Sized Combustion Plants

The MCPD was introduced by the European Union to reduce emissions from medium-sized combustion plants, specifically those with a net thermal output between 1 MW and 50 MW. These plants, which are commonly used in industries such as district heating, industrial processes, and many manufacturing applications, represent a significant source of emissions if left unchecked.

The Directive became UK Law in 2019 using an amendment to existing Environmental Permitting Regulations.

The MCPD sets strict emission limits for key pollutants, including:

- NO x (Nitrogen Oxides)

- SO x (Sulphur Oxides)

- Particulate Matter (PM)

KEY COMPLIANCE DATES TO CONSIDER:

• 20 December 2018 for all new plant

• 1 January 2025 for existing plants between 5MW and 50MW

• 1 January 2030 for existing plants 1 to 5MW

To help businesses meet these limits, the directive stipulates that plants must either reduce emissions through better technology or switch to cleaner fuels. Failure to comply with these limits could lead to significant penalties, including fines and potential operational shutdowns. However, it’s important to note that the MCPD offers flexibility, allowing industries to meet the emission standards through various methods, such as retrofits, upgrades, or fuel-switching without incurring prohibitive costs.

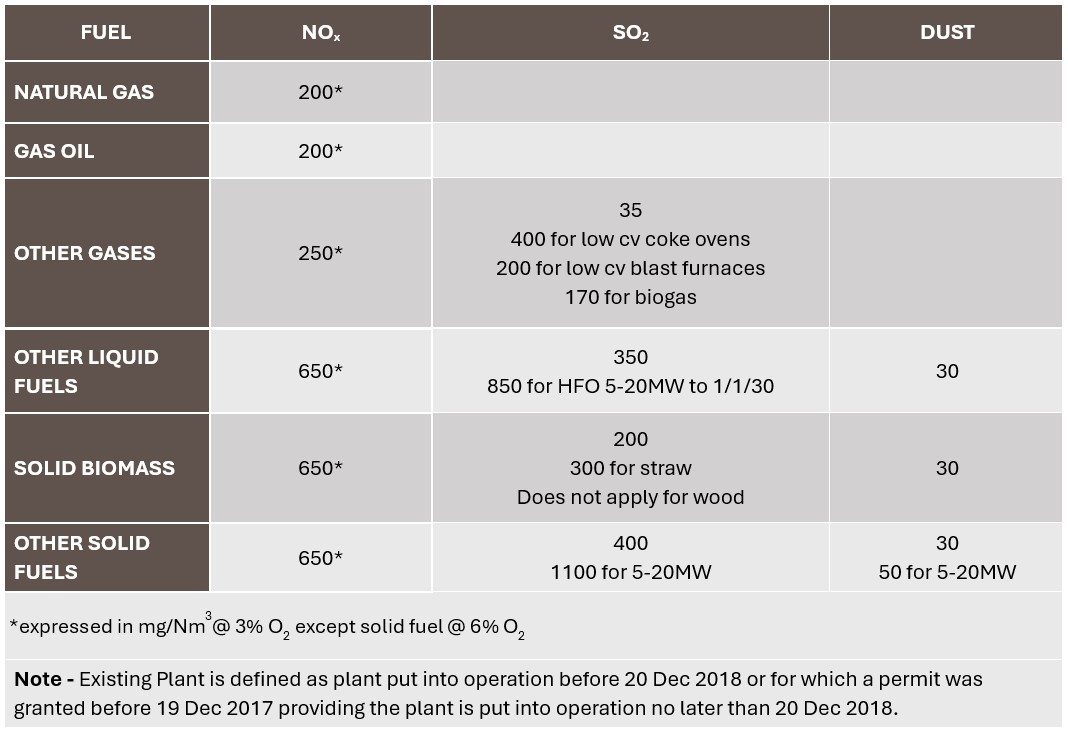

MCPD Emission Limit Values

Existing burner/boilers 5-50MW nett thermal input

How Businesses Can Achieve Compliance Through Efficient Design and Retrofitting

One of the key pathways for businesses to achieve compliance with the MCPD is through retrofit solutions—upgrading existing combustion systems with the latest emission-reducing technologies such as SAACKE SCanView or se@vis controls. Retrofitting existing boilers with low-NOx burners, Flue Gas Recirculation or treatment systems, and heat recovery technologies can be a cost-effective way to bring aging equipment in line with new regulations.

Retrofitting is often preferable to replacing an entire combustion system, especially for small to medium-sized businesses looking to limit capital expenditures.

- Low-NOx Burners: These are designed to optimise fuel-air mixing and combustion temperatures, which helps reduce the formation of nitrogen oxides (NOx). By switching to a SAACKE low-NOx burner, industries can immediately reduce harmful emissions without sacrificing efficiency or productivity.

- Air-Fuel Ratio Controls: Advanced control systems like SCanView and se@vis can constantly and automatically adjust the air-fuel ratio of your burners, to guarantee you stay within the ELVs. Direct Digital Combustion Control (DDCC) is a ‘must-have’ for modern day boiler management.

- Flue Gas Recirculation (FGR) reduces both the oxygen partial pressure, by increasing the proportion of inert gas in the combustion zone, and the flame temperature, which in turn greatly reduces the production of Thermal NOx. This can be retrofitted to many burner designs and has the greatest effect on Gas and Light Fuel Oil fired equipment.

- Flue Gas Treatment Systems: Selective Catalytic Reduction (SCR) and Selective Non-Catalytic Reduction (SNCR) technologies are essential for reducing NOx levels in the flue gases. These systems inject a reductant (such as ammonia or urea) into the exhaust gases to chemically convert NOx into nitrogen and water, ensuring compliance with MCPD regulations.

- Particulate Matter (Dust) Filters: The directive also mandates the reduction of particulate emissions. Adding or upgrading electrostatic precipitators or fabric filters can significantly reduce particulate matter, which is harmful to both human health and the environment.

The SAACKE solutions are designed with retrofit potential in mind. Our low-emission burner systems and fuel-agnostic approach provides businesses with a comprehensive suite of tools to meet MCPD compliance while improving energy efficiency and reducing fuel consumption.

Benefits of Adopting Low-Emission Technologies to Meet MCPD Requirements

Adopting low-emission technologies doesn’t just ensure compliance with the MCPD—it also offers numerous long-term benefits for businesses, including:

- Cost Savings: Modern combustion systems, such as those equipped with low-NOx burners and flue gas treatment, operate more efficiently, reducing fuel consumption and lowering operating costs. These savings can offset the initial investment in new technologies and lead to long-term financial benefits.

- Improved Operational Efficiency: By optimising combustion processes through advanced burner control and flue gas treatment, businesses can achieve better thermal efficiency, translating into reduced energy consumption and fewer emissions.

- Sustainability and Corporate Responsibility: Adopting low-emission technologies helps businesses align with global sustainability goals. Reducing emissions contributes to a greener reputation, which is increasingly important in today’s environmentally conscious market.

- Future-Proofing: As environmental regulations continue to tighten, industries that adopt advanced combustion technologies now will be well-positioned for future compliance with even stricter regulations. This reduces the risk of regulatory penalties and provides peace of mind for business leaders.

- Compliance with Local and Regional Regulations: While the MCPD is an EU-wide regulation, it is part of Internationally recognised treaties and agreements and many countries and regions have their own environmental standards. By adopting low-emission technologies, businesses ensure compliance not only with the MCPD but also with other local and international emission standards, protecting their operations across multiple jurisdictions.

Exciting Times for the Future

The MCPD is more than just a regulatory hurdle—it’s an opportunity to innovate and improve operational practices. As industries face increasing pressure to meet sustainability targets and reduce emissions, the adoption of cutting-edge combustion technologies is a key strategy for staying competitive and compliant.

By focusing on efficiency and emission reductions, businesses can not only navigate the regulatory landscape but also create a more sustainable and profitable future. For us here at SAACKE, the MCPD represents an exciting challenge—one where our ultra-Low NOx advanced burner technologies, automated control systems, and retrofit solutions play a pivotal role in helping industries meet their compliance goals.

With the right approach, businesses can turn compliance with the MCPD into an opportunity for innovation, cost savings, and sustainability, positioning themselves as leaders in a cleaner, greener industrial future.

Want to Know More?

If you are interested to know more about the MCPD regulations and how they will directly affect you or your business, Contact our team today and we can arrange a more in-depth presentation for you, or organise an initial free on-site consultation.